Listen up, and don’t forget non-digital workers

By

— October 10th, 2017

Register now for our December 19th webinar, Formica's Laura Barbour will take attendees through the journey to successfully communicating to - and engaging non-desk employees.

Do non-wired employees really matter?

Back in the 1970s our working population looked very different to today. It consisted of 70% manual workers and only 30% professional. In terms of employment, it was a time when there was stability, loyalty and a job for life. Back then there wasn’t even a whisper of ‘Employee engagement’.

Now let’s look at the turn of the new millennium. As industries declined and the corporate world increased we saw a 50-50 mix of professional and manual workers. Gone were the ‘jobs for life’ and in its place came ‘restructures and redundancies’. We had a digital workforce that was facing market change and job insecurity and with that came the need to ‘engage’. But what are our tools of engagement?

Let’s look at you… the wired employee. You are possibly sitting at your laptop reading this online during your working day. You may have your smartphone beside you too. You may be attending a virtual meeting today at some point; talking to your colleagues via spark or reading something on yammer. You may have watched the latest video blog from your CEO or be looking at an intranet that’s ‘tailored to suit your needs and interests’.

Communicating effectively in the workplace

So what if we were to take all that away – what would you have left?

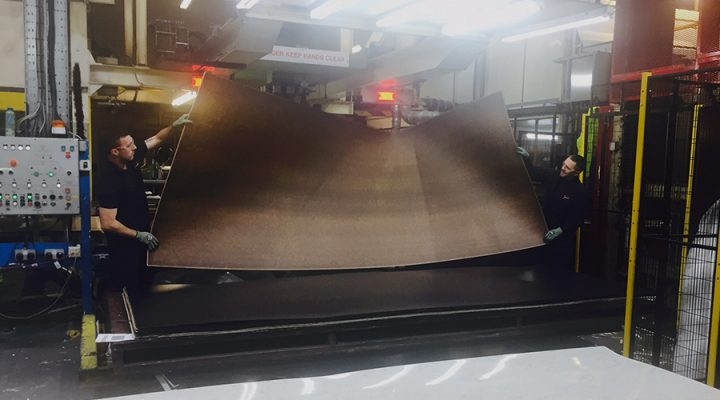

The reality is, for every person like you, there is someone working in a very different environment: the non-wired manual employee. They might be in our shops, our garages, fixing and building our roads, cleaning our water, delivering our mail, producing our food, building our cars and making the products we use in our homes and at work. How do we engage them? And are we even thinking about it? Because we know they are harder to engage.

This blog is going to focus on just one pocket of this community – our manufacturing employees. In the UK, over 2.7 million people are currently employed in a manufacturing environment. Although it has been declining since the 1970s the UK is still the ninth largest manufacturing nation in the world. Yes, the world.

Welcome to our world…

Here are some insights into manufacturing employees here at Formica Group Europe.

- Our manufacturing sites operate 24 hours a day, five days a week – often at weekends if we see high customer demand

- Our employees operate and rotate over three shifts so we never have everyone on site at the same time

- Our operatives work on the shopfloor in pairs and with hearing protection so they can’t hear anyone talk – especially over very loud machinery

- Our operatives are not allowed mobile phones on the shopfloor – if they are looking at their phones they are not working safely and safety is key

- Our working environment is heavily unionized with little appetite to communicate outside of working hours – it’s not uncommon to see a queue at the clocking out machine at the end of a shift

- We have an aging workforce with 51% of employees over the age of 50 and 52% have more than 10 years’ service.

Our levels of engagement

Back in 2015 our business was facing an urgent reality to change. With the recession impacting customer demand in our main regions we were no longer making money. In our main manufacturing site in the UK employee engagement was 49%, confidence in our senior leadership team was at 28%, only 23% of employees stated we had a clear vision, and only 43% felt informed about the company.

On top of that, our scrap rates were at 9% and employee absence was 7%. A new leadership team had been put in place to develop and implement a recovery plan for our main manufacturing site. Within 12 months we had delivered great results.

Seek first to understand... and then be understood

It feels too simple to say but our trick to developing an engagement recovery plan was to listen. Myself and the new HR Manager for UK, Michelle Robson, set up three listening sessions (with a perceived group of ‘reds’, a group of ‘amber’ and a group of ‘greens’).

The aim was to identify a consistent set of themes which we needed to address. The conversation focused on what is ‘good’, ‘bad’ and ‘ugly’ about working here. We were in each session for up to three hours and met with the groups again a week later to sense-check our findings before we shared them widely.

Our new COO and Plant Manager supported our plans to improve the key themes (culture, communication, training and working conditions). As we developed improvement plans on these areas (to form part of the overall recovery plan) we were ready to launch a number of new communication channels. Each designed to deliver agreed outcomes.

I’m aware: I have the information to do my job and I’m kept informed on what’s happening across the business.

•Communication stations installed at all clocking in machines where employees can pick up a paper copy of news and take it with them to read;

•Informed weekly news from Plant Manager to talk about site activity, key dates, updates on;

•‘Read Me’ updates for any announcements taking place (people change and strategy);

•Digital screens on shop floor high traffic areas to share posters / campaigns

Toolbox Talks for any topic specific briefs which needs to be shared with shop floor i.e. Safety updates.

I understand: We have regular time as a team to talk about what is happening around us.

• Start of shift briefing out on the shopfloor supported by Team Leaders which covers off daily activity, safety, production, labour, and quality.

I’m supported: We have a two way conversation on what is happening in my department.

• Department Team Talks which take place each quarter out on the shopfloor. Department Manager gives an update on performance and plans for that department and any changes coming up.

I’m involved: I get the opportunity to talk about me, my role, my objectives, my concerns. I am up to speed on latest management discussions.

• Develop non-wired performance framework which will launch capability framework and 121 performance conversations

I’m committed: I have an opportunity to take part in discussions on our strategy, plans and ideas for improvement.

•Full site Team Talks each quarter where employees get an hour off the shopfloor to come together and talk about our performance and our plans

Did we improve?

The initial reaction was overwhelming. Within the hour of us hosting our first Team Talk with the new leadership team we were receiving messages via the Unions to say the feedback on the shopfloor was extremely positive. We made a commitment to doing Team Talks every six weeks which is a huge commitment given the recovery improvements we needed to make (1 hour for the whole of the shopfloor = 27 days production time).

Sixteen volunteers from the shopfloor also came forward to get involved in the key theme improvements and became champions. This group did a great job at challenging the pace of our improvements but were also fundamental in driving the right outcome and updating their colleagues on progress. On the engagement side our score went up by 14%. Confidence in our senior leadership team rose by 47%, having a clear vision rose by 41% and being informed by 26%.

Behind the scenes, the leadership team began to secure investment from our parent company, Fletcher Building, to deliver the manufacturing improvements we needed to make (NZD$40m investment has now been secured to date). Our scrap figures dropped from 9% to 4%. On top of that we had seen a reduction in ‘lost time’ safety incidents, saved NZD$2.1 million in one year on absence and reduced our scrap rates from 9% to 4%.

Communicating effectively in the workplace

My message to you…

So as we sit here discussing the latest digital advances; monitoring click through banners; forum debates and online comments… remember to think about your remote workers.

They may be in cars, in labs, out with customers or like Formica... out on the shopfloor. Keep time on your agenda to understand what works for them.

Why not step into their world and create communications channels which are designed specifically to meet their needs – it really does matter. But remember, with any improvement comes the expectation to deliver further improvements.

We still have areas that are broken and need a lot attention. Our plans this year focus on our middle management and still on training (it’s a long haul fix) but we actively listen and pay attention to the voice of our employees.

Their opinions are key to us creating a better place to work.

Register now for our December 19th webinar, Formica's Laura Barbour will take attendees through the journey to successfully communicating to - and engaging non-desk employees.

Poppulo says: If you would like to hear about how to overcome the challenges of communicating with employees beyond your HQ, you can download our FREE white paper here: