By Tim Vaughan

— August 1st, 2024

Poor quality in a production process, whether its automobiles, satellites, or hairdryers, costs companies valuable time and money.

Hand-in-hand with substandard quality is the need for rework–the unnecessary redoing or fixing a product that should have been correct in the first place–and together they can cost companies millions of dollars.

According to the American Quality and Productivity Center (AQPC), rework and scrap can equate to 2.2% of a company’s revenues: $32m a year for an organization with annual sales of $2b–and that’s not including layers of other significant costs due to logjams, delayed production, and missed deadlines.

No wonder companies go to extreme lengths to implement benchmark quality control processes that cut down on rework.

Increasingly, manufacturing operations across all types of industries and sectors are seeing the benefits of digital signage as a critical tool for meeting the highest quality standards and minimizing the inefficiencies and costs of unnecessary rework.

The Advantage of Digital Signage

At Poppulo, we have a front-row seat on the compelling advantages of digital signage in all types of manufacturing, because Poppulo Harmony’s Digital Signage is used by many of the most successful companies in the world–for whom the most exacting quality standards are table stakes.

Take Northrop Grumman Corporation (NGC), the American multinational aerospace and defense technology company, which employs over 100,000 people globally and has annual revenues of over $30b.

When you’re sending incredibly expensive satellites into space, you can’t afford to mess up on the manufacturing floor. Quality is everything. Which is why Northrop Grumman made the decision to deploy Poppulo’s digital signage at its Space Park facility in Redondo Beach, California.

“We're sending stuff into space. We can't send repair people to go and deal with something if it doesn’t work exactly as it’s designed to. That’s why quality is so important to us—once it's launched, it's launched. Anything we can do to help reduce the time it takes to produce a product and ensure its quality—that’s meaningful to Northrop Grumman. And that’s why we use digital signage on our production floor,” said Oscar Castillo, Factory Modernization & Digital Transformation Project Manager, Northrop Grumman.

Find out more on how NGC capitalizes on the benefits of digital signage here.

The Benefits of Signage

For an alternative real-life example of the benefits of digital signage both from a manufacturing and employee communications perspective check out how Roselin & Associates, the global manufacturing construction company, uses Poppulo’s digital signage.

Any reference to companies that pursue optimal efficiency for optimal quality–consequently minimizing the need for rework–Toyota must be highlighted. The Toyota Production System (TPS) revolutionized global manufacturing processes.

The philosophy at the core of TPS is to eliminate waste and achieve the best possible efficiency, and is based on 14 key principles, one of which is visual management– visual indicators that quickly convey information, allowing for immediate understanding and action. The principle is rooted in the belief that problems can’t be solved if they aren’t visible.

In the early days of Toyota’s TPS development, these visuals were static information boards–posters or cardboard. But today they are deployed through digital signage in all its manufacturing plants.

Digital displays provide real-time updates on production metrics, quality control alerts, and step-by-step assembly instructions. By ensuring that all employees are aware of the latest information and procedures, Toyota minimizes errors and rework, maintaining high standards of quality. This results in improved production efficiency and a significant reduction in defects and rework rates.

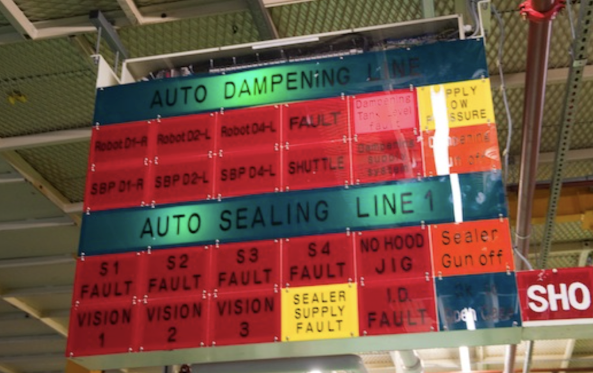

Picture courtesy of Toyota UK Magazine.

So, let’s have a closer look at the many concrete advantages and effectiveness of digital signage for quality control and slashing rework costs.

Effectiveness of Digital Signage for Quality in Manufacturing

At the risk of stating the obvious, in manufacturing, clear and effective communication is critical to maintaining high-quality standards and minimizing the need for rework. Here's how digital signage through the Poppulo platform helps reduce rework and improve quality:

Instant Updates: If everything isn’t going smoothly or if there’s a production problem, it’s essential that people are alerted to it quickly and clearly. For example, if there's a sudden change in the production process, such as a modification in the assembly line procedure, it can be communicated instantly to all relevant employees via digital screens.

Visual Instructions: Complex instructions can be simplified and communicated more effectively through visual aids. Digital signage can display diagrams, videos, and animations that show step-by-step procedures, making it easier for employees to understand and follow.

For example, an instructional video on a digital sign can demonstrate the correct way to assemble a component, ensuring that workers understand the process and execute it correctly the first time.

Quality Management: By displaying key performance indicators (KPIs), production metrics, and quality data in a visually appealing format, digital signage helps employees to quickly identify areas for improvement. For example, a large-screen display showing real-time quality data can help motivate teams to do their best work.

Data-Driven Improvements

Continuous improvement and optimal quality are best achieved through performance data and when employees are empowered with feedback loops to highlight problems and suggest ways of doing better. Digital signage delivers on both counts.

Feedback Loops: When employees can report issues or suggest improvements directly through the system, this real-time feedback can be invaluable in identifying and addressing quality issues quickly. For example, a touchscreen digital sign can allow workers on the manufacturing floor to report defects or procedural issues immediately, enabling faster corrective actions and reducing rework.

Centralized Control, Consistency & Customizable Content

A centralized digital signage platform ensures that all information displayed across the facility is consistent and up-to-date. This uniformity helps prevent discrepancies that can arise from manual updates or word-of-mouth communication. For example, instead of relying on supervisors to communicate changes verbally, a digital signage system can ensure that every worker sees the same updated procedures or safety protocols simultaneously

Customizable Content: A key benefit of digital signage is that it allows for easy customization of content to address specific needs or issues as they arise, for specific target audiences across the organization, wherever they work.

If a particular quality issue is identified, targeted messages and reminders can be displayed to address the problem immediately. For example, if a recurring error is detected in a specific part of the production line, customized messages can be displayed at relevant workstations to remind workers of the correct procedures.

Conclusion

In summary, a centralized digital signage management system is one of the most effective means of ensuring optimal quality and slashing rework costs in manufacturing, and it’s why Poppulo’s digital signage platform is a favored partner of the most successful manufacturing organizations.

If you would like to find out more about how we can do for you what our digital signage does for the best manufacturing companies in the world, you can contact us here. We’d love to tell you more!